Since the 1920s, bakeries have been taking advantage of the benefits of bread enzyme technology. As time went on, the use of enzymes has become increasingly important for industrial bakeries. Initially, enzymes were included in ingredients. But in the 1980s, manufacturers began to isolate and manufacture individual enzymes. This technology has proven to be highly cost-effective and efficient in enhancing the quality of baked goods while reducing production costs.

Why enzymes instead of emulsifiers:

Bakery enzymes offer many advantages to bakeries that make them a better choice than emulsifiers. Their natural ingredients are effective in improving the texture, taste and shelf life of baked goods, but they offer also some specific advantages compared with emulsifiers:

-

They are very versatile and focused – each enzyme has a specific function and virtually no side effects.

-

As technical aids they enhance functional bread properties. And since they’re inactivated during processing, they don’t need to be declared on labels.

-

The enzyme technology field is very dynamic with much research and development being done. In contrast, emulsifiers have been around since the 1960s and have experienced very little development.

Working with enzymes can be quite complex due to their sheer number. We typically use distinct enzyme families that interact with starch. Each of these families contains different varieties. Taking the time to understand the nuances of each enzyme family can be a challenging but rewarding process.

How flour enzymes can be used in the baking process:

Enzymes are specific in their applications. Some react with proteins, others with fibres, fats or gluten. Depending on the needs of the recipe and baking process, different types of enzymes should be used. Knowing which combination of enzymes to use can be a challenge. Many commercially available enzymes used in baking industry are cocktails of different enzymes. Producers of enzymes may not be aware of how their enzymes interact with other ingredients during the baking process. To make sure that the right combination of enzymes is used, it is important to fully understand the characteristics of each enzyme and their impact on the entire baking process. That is where Zeelandia comes in!

At Zeelandia, we use enzymes in many of our products, including bread improvers. We have a selection of ready-made bread mixes that are perfect for smaller and medium-sized bakeries. Finding the perfect enzyme for each situation no longer has to be a daunting task.

For industrial bakers, this challenge can be even greater. Many have their own flour and a more complex production process. That's why we develop tailored solutions together with you, ensuring an in-depth selection process of the right enzyme.

To make this process easier and more efficient, our researchers have undertaken an ambitious project. We have compiled an extensive database of all commercially available enzymes, detailing their makeup and characteristics. We call this enzyme mapping.

How enzyme mapping works

At Zeelandia, our researchers are constantly testing and developing new enzyme formulations to help industrial bakers improve their baking processes and products. We use state-of-the-art technology and equipment to analyse the effects of different enzymes on the dough and final product. Our testing process includes sensory evaluation, texture analysis and shelf-life testing to ensure that our enzyme formulations meet only the very highest standards of quality.

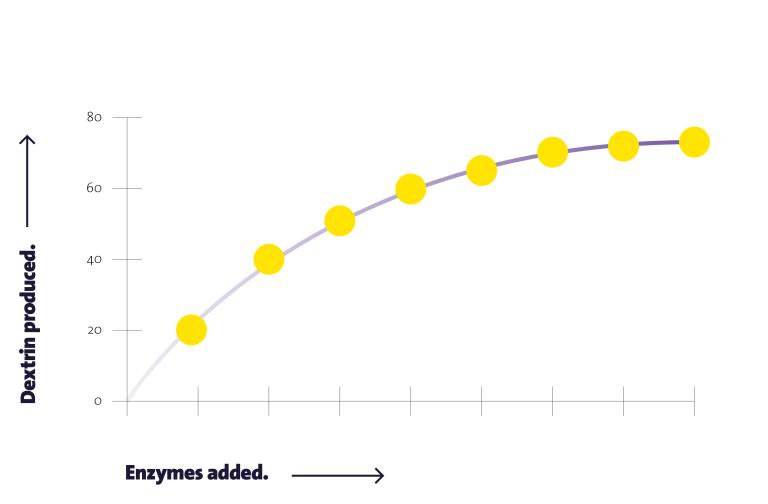

We have taken the time to measure the activity of enzymes in various settings. Our research has shown how each family of enzymes reacts to different pH values and how breaks down the same molecule. Additionally, we have studied the digestion profiles of different enzyme families, and have come to understand the unique fingerprint of each. No more guessing necessary!

How enzyme mapping can assist you

We are always looking for ways to enhance the quality of bread improvers, and the latest advancements in enzyme mapping have allowed us to do just that.

-

By identifying the exact enzymes required for a particular recipe and production process, we can remove any unnecessary elements and streamline the development process for better, faster results.

-

By being able to predict the performance of enzymes for different types of flour, we can make swift adjustments whenever there is a switch.

The data we have collected through our enzyme mapping has not only provided us with comprehensive information for applications in bread, but has also given us great advantages when it comes to tailoring bread improvers to our customers' individual needs. With our comprehensive database, we can quickly identify more accurate refinements and make adjustments faster than ever before. This is a major customer benefit –bread improvers will always be tailored to each customer’s specific circumstances and provide them with the best possible results.

If you are interested in learning more about how enzyme mapping can improve your baking process and the quality of your end product, please reach out to us!