In the context of an industrial bakery, any solution has to be tailor-made, and fruit fillings and jams are no exception. To ensure a high, consistent quality, a filling or jam needs to be a perfect fit at every stage of production: from its processability on an existing production line to its stability and interaction with other ingredients, dough or decoration. And from the specific challenges of interrupted baking processes to the required shelf life of the end product.

It’s also important to make sure a filling of jam is in line with specific product claims or requirements. For example, should the end product be clean-label, free of additives? Does the bakery want to be able to make specific product claims, such as ‘reduced sugar content’, ‘rich in fibre’, ‘sustainably sourced’, ‘low carbon footprint’, 'without palm-oil' etc?

How does Zeelandia create a solution that works for each individual bakery?

We first of all sit down with a customer to discuss ideas for a new product, taking into account consumer trends as well as the customer’s existing product portfolio and production infrastructure. We define the requirements for a fruit filling or jam. At this point we make the difference by designing a filling or jam to exactly the right specifications, and by offering technical support each step of the way, from a first test to the first few full production runs.

1. Finetuning taste and texture

Zeelandia’s Fruitful portfolio includes fillings and jams in dozens of different flavours and across a range of textures. These can be finetuned to suit local tastes. We can adjust the percentage of fruit content, and textures can be adapted to a bakery’s exact specifications: do we want the filling to be smooth, to contain whole pieces of fruit, or cubed or chopped (and to what size?). What mouthfeel does a jam need? And we can even prepare a mix of several fruit/berries, even with inclusions of herbs and/or spices.

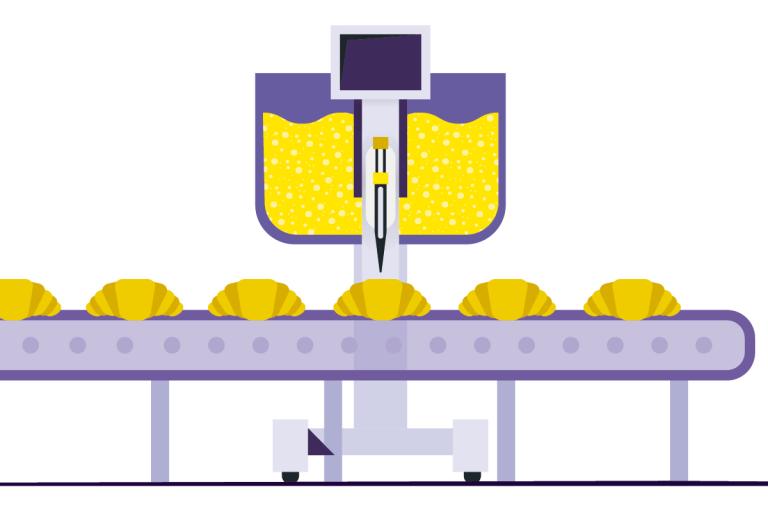

2. A smooth production process

Important choices here include the required viscosity of a filling or jam. What consistency will work with the bakery’s existing equipment for piping, spreading or injecting? And how will the various characteristics of a filling or jam interact with other ingredients in this particular recipe? For example, we take into consideration how parameters such as water activity (and its interaction with the filling and the dough), affect both the flavour, consistency, baking properties and visual appearance of the baked product.

3. Optimising shelf life

There are two types of shelf life to consider. Zeelandia’s fruit fillings or jams themselves, depending on the packaging, have a shelf life ranging from 6 months to 2 years, thanks to a unique packaging process. Perhaps more challenging is achieving the desired shelf life of the end product. Here we can adjust key parameters such as sugar content and water activity – but since these also impact flavour and texture, we make sure to hit the exact sweet spot, where the end product ticks all the boxes.

4. Making healthy and natural choices

Research indicates that 67% of bakery companies are interested in clean label claims for pastry products. Zeelandia helps them by finding ways of improving nutritional profiles without loss of flavour, using natural sweeteners, natural colours and flavours, and through packaging methods that allow us to reduce or eliminate the need for preservatives or additives.

5. Tailored packaging

Speaking of packaging: fruit fillings and jams can be supplied in piping bags, bags in box, buckets, tins, drums or containers, in volumes ranging from a few kilos to 1,000 kg. The type of packaging used will not only be determined by what will fit the bakery’s workflow, but also by the required shelf life of the filling or jam, which can be up to 2 years at ambient temperatures. And for customers who share our ‘Zero Waste’ ambition, we offer a range of recyclable, reusable or returnable packaging materials.

Take the next step.

Choosing Zeelandia means selecting a partner dedicated to excellence, innovation, and sustainability. Our tailored approach ensures that every bakery can deliver exceptional products that stand out in the market. We invite you to experience the difference that tailor-made fruit fillings and jams can make in your products. Contact Zeelandia today to begin your journey towards customized excellence, and let us help you turn your baking visions into reality. Together, we can craft flavors that resonate and endure.